Planet Loomis

Misc ramblings on what's going on in the Loomis household.

Saturday, December 08, 2007

Wednesday, May 09, 2007

Tuesday, October 10, 2006

Friday, September 29, 2006

The WVO project is no more

The title says it all. After some considerable thought I decided that converting the modern TDI engine is simply too risky. After all, I have goals to keep this car forevever, which is in direct conflict with running grease. Anyway, there are too many people on the TDIClub website that are killing their IPs, and worse, melting their pistons. Ouch!

Monday, August 07, 2006

Google maps is updated...

...with a satellite image of our new home, which is only 2 months old. This shot shows the foundation and possibly some framing. Pretty cool.

Friday, August 04, 2006

Look Busy

This was in the latest Wired magazine...funny, funny stuff.

There's an easy formula for becoming a slacker: Do nothing. Go get more coffee. Repeat. But how can you slack and still keep your job? It's all about appearances. Dilbert creator Scott Adams lists low-impact ways to look like an overachiever.

Complain that you're totally swamped at every opportunity. Use phrases like "up to my ass in alligators" and "jumping from one fire to another" to make your job sound kind of sexy and dangerous.

Carry a piece of paper wherever you go. To give yourself the necessary urgent facial expression and body language, imagine it's something incredibly important, like a stay of execution from the governor.

Never clean your cubicle. After all, if you had any spare cycles you wouldn't let yourself live like a pig.

Emailing looks like work. Email friends and family often.

If you feel like talking instead of working, talk to your boss. That counts as work no matter what you're chatting about. The ideal topic of conversation is how poorly all of your coworkers are performing.

If you wear glasses, leave an old pair on the desk as though you will be right back. Then go home.

Leave voicemails for coworkers at 1:00 am, even if you're getting up just to take a whiz. If you really want to inspire awe, leave a message for your boss with your thoughts on the company's outdated filing system at 11:30 pm on New Year's Eve.

Be sure to get involved in unquantifiable projects. You want to be doing a lot of consulting and advising and attending. Avoid anything with a hard and fast deadline.

Learn to sleep with your back to the cubicle entrance. You'll have to practice to keep your head from slumping over, but it's worth it. If you can't pull that off, try a neck brace painted the same color as your skin.

Bitch about your job as much as possible. This is considered work even though it's fun.

Tuesday, June 06, 2006

Sunday, June 04, 2006

Tuesday, May 16, 2006

Wow - major problems *already*

Wouldn't you know it, but as soon as I relocate the washer reservior I start getting problems. Some troublesome, some outright problematic. The short list:

- An air gap would appear in the line, preventing the pump from working properly.

- There appeared to be a parasitic drain issue, killing the battery overnight.

- The fluid hose would leak at several places.

- Electrical tape pulling loose at several solder joints.

- Relocate the resevior intake line to the side-bottom of the bottle. The hose no longer loops over the top, rather it all stays low.

- Use only minimal solder - too much creates resistance issues in circuits.

- Stay away from the electrical tape - shrink tube is much cleaner and a hell of a lot more effective.

- Two words - compression adapters. Thinking that simply sliding a 3/8" tube inside a 1/2" adapter tube was stupid.

Monday, May 08, 2006

A view of the washer reservior installed

And here it is installed next to the battery. It's a *perfect* fit. Notice the red tie-down strap with a ratcheting tightener. It goes all the way around the battery compartment. You don't see it here, but I have the pump secured to the other side with 2 zip ties.

The tube comes out of the container, under the tank, and finally connecting with the bottom of the pump. It works pretty well once the entire fluid line is primed, but it eventually gets a large enough air bubble at the top of the container to force a long pump time to get things started each time. The ultimate goal is to minimize this hose length. I'll have to rework this eventually.

My new windshield washer reservior

Here's a shot of the Naglene bottle with the "low fluid level" sensor installed. That part was easy - especially if you have high speed rotary tool. Just cut a comparable hole (1"), take the rubber grommet out of the OEM tank, and plop it in with the sensor. But don't cut the hole too big, otherwise you'll be forced to break out the silicone sealant. Don't ask me how I know. ;->

The conversion has begun!

Alright - it's time to get my nose out of the books and back where it belongs - under my car hood. After quite of bit of research I determined that the best place for all the components in a Jetta (A4) is as close to the injection pump as possible. The problem is there is limited room to place all of this stuff, especially the heated fuel filter and/or heat exchangers. You see, those things get quite large depending on what you go with.

Then I found this site. What a great idea! Relocating the the windshield washer reservior fixes the bulk of the space issues. The only problem is the OEM bottle is simply too large to move. Time to build my own. ;-)

The Nalgene bottle you see here is almost perfect. It's large enough to hold a reasonable amount of fluid, *very* durable, and it fits in quite well near the battery. I'm happy...

Friday, April 28, 2006

Edit->Undo

Undo the last post...I just can't bring myself to buy a kit. There is just too much engineer in me. So, back to the drawing board, so to speak.

Wednesday, April 26, 2006

Frybrid or Custom?

I've been back and forth about whether to buy an off the shelf kit, build my own, or cobble together some combination thereof. As you can see from my previous post, I was going down the "build my own" path. That is, until this post.

The margin for error is honestly very low with WVO conversions. Looks like I'm going with the Frybrid solution due to best in class engineering/parts, and most importantly, an on-board controller that intelligently switches between the two fuel systems.

Wednesday, April 19, 2006

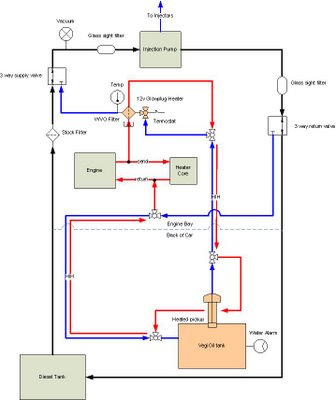

I think I've finalized my WVO setup, the key features include:

- Custom vegoil fuel pickup

- Custom vegoil fuel tank (plastic or steel)

- Custom Hose in Hose fuel line (HIH)

- Custom heated fuel filter

- Dual 3 way fuel valves (Frybrid)

I'll build a few prototypes just to be sure I don't fsck something up. :)

Monday, April 10, 2006

Do It Now!

I found this post especially inspriring. So much so that I've started to implement some of the suggestions. Especially those items under "Do It Now!" and "Failure is your friend". I'll check back and post my results....hopefully there will be some growth in this area. I need it. ;->

http://www.dexterity.com/articles/do-it-now.htm

Friday, April 07, 2006

How not to ask for help

This is a *perfect* example of how *not* to ask for help on an Internet forum. This particular forum deals with waste/straight vegitable oil conversions for diesel engines.

http://www.frybrid.com/forum/showthread.php?t=3770&page=1&pp=10

Frybrid - looks to be the best kit out there, and I'll most likely do it for my 2000 Jetta TDI.